Comments

- No comments found

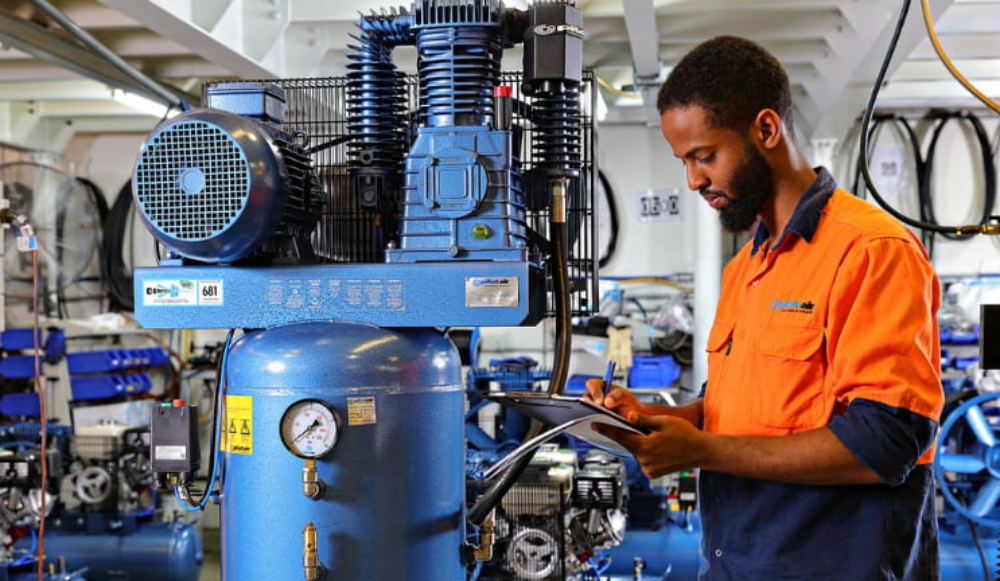

Air compressors are indispensable tools in various settings, from home workshops to industrial facilities.

Whether you use it to inflate tires, power pneumatic tools, or for other applications, maintaining your air compressor is crucial. Regular upkeep ensures optimal performance, extends its lifespan, and prevents unexpected breakdowns that could disrupt your work or projects. This comprehensive guide will provide you with essential tips and insights on air compressor maintenance, helping you get the most out of your investment. For more complex issues or when professional assistance is needed, consider contacting an air compressor repair service.

An air compressor is a significant investment, and like any investment, you want to protect it. Proper maintenance helps prevent wear and tear, ensuring your compressor continues to deliver consistent, reliable performance for years to come. Neglecting maintenance can lead to premature failure, requiring expensive repairs or even replacement.

A well-maintained air compressor operates more efficiently, consuming less energy. This translates to lower operating costs and a reduced environmental footprint. Regular maintenance tasks such as cleaning air filters and checking for leaks can significantly impact your compressor's energy consumption.

Regular maintenance also ensures the safe operation of your air compressor. Malfunctioning components can pose a safety hazard, potentially causing injury or damage to property. By adhering to a maintenance schedule, you can identify and address potential issues before they escalate into dangerous situations.

The most fundamental step in air compressor maintenance is to thoroughly read and understand the manufacturer's manual. It provides specific instructions and recommendations for your particular model, including maintenance schedules, recommended lubricants, and safety precautions.

Air filters capture dust, debris, and other contaminants that could wreak havoc on your machine. Over time, they become clogged, hindering airflow and diminishing your compressor's efficiency. To maintain optimal performance and prevent premature wear, it's crucial to inspect your air filters regularly and replace them according to the manufacturer's recommended schedule. A clean air filter not only boosts efficiency but also safeguards your compressor from repairs.

Moisture accumulation within your air compressor's tank is a silent threat that can lead to severe damage. This insidious buildup can foster the growth of rust and corrosion, compromising the integrity of the tank and degrading air quality. To mitigate these risks, it's essential to drain the tank regularly, especially in humid environments. Most compressors are equipped with a drain valve conveniently located at the bottom of the tank. By performing this simple task, you'll safeguard your investment and ensure a consistent supply of clean, dry air.

If your air compressor relies on belts to transmit power, regular inspections are paramount. Over time, these belts can experience wear and tear, leading to decreased performance and potential breakage. Loose or worn belts reduce efficiency and place additional strain on other components. To prevent costly repairs and downtime, you have to inspect your belts for signs of damage and tighten or replace them as needed. Adherence to the manufacturer's guidelines will ensure optimal belt tension and prolong the life of your compressor.

Your air compressor's hoses and connections are susceptible to wear and tear, creating potential vulnerabilities in your system. Regular inspections are essential to identify leaks, cracks, or other signs of damage. Even minor leaks can lead to significant pressure loss and reduced efficiency, while more severe issues can result in equipment failure and safety hazards.

Proper lubrication is essential for maintaining the smooth operation of your air compressor's moving parts. It reduces friction, minimizes wear and tear, and extends the life of critical components. To ensure optimal performance, use the recommended lubricant and adhere to the manufacturer's lubrication schedule. Neglecting lubrication can lead to premature component failure.

If your air compressor is equipped with an oil-lubricated pump, maintaining adequate oil levels is crucial. Insufficient oil can lead to overheating, reduced performance, and even catastrophic failure. Conversely, overfilling the oil can create problems as well. To prevent these issues, regularly check the oil level and top it off as needed using the recommended oil type.

While often overlooked, maintaining a clean exterior is important for the overall health of your air compressor. Accumulated dirt and debris create a breeding ground for contaminants that can find their way into the internal components. By regularly cleaning the exterior with a damp cloth and mild detergent, you can help prevent these issues and maintain optimal performance. A clean compressor also presents a professional appearance and reflects a commitment to proper equipment care.

Safety valves protect your air compressor from excessive pressure buildup. These devices are designed to release pressure when it reaches unsafe levels, preventing potential damage and hazards. To ensure the proper functioning of these valves, it's essential to test them periodically. Consult your owner's manual for specific instructions on how to perform these tests.

While diligent preventive maintenance can extend the life of your air compressor, it's still necessary to schedule regular professional inspections and maintenance. A qualified technician can perform a thorough evaluation of your equipment, identify potential issues, and address any necessary repairs. By investing in professional maintenance, you can avoid costly breakdowns, optimize performance, and ensure the safety of your equipment. When searching for air compressor installation near me services, consider inquiring about their maintenance offerings as well.

By following these comprehensive maintenance guidelines, you can significantly extend the lifespan of your air compressor, optimize performance, and minimize the risk of costly repairs.

Beyond the essential maintenance tasks, there are several additional tips you can implement to ensure your air compressor remains in optimal condition:

Store Properly: When not in use, store your air compressor in a clean, dry environment. Protect it from extreme temperatures and moisture.

Use a Surge Protector: Connect your air compressor to a surge protector to protect it from electrical damage.

Replace Worn Parts: Don't hesitate to replace worn or damaged parts promptly. This can prevent further damage and extend the life of your compressor.

Invest in Quality: When purchasing a new air compressor, choose a reputable brand known for quality and durability. This can save you money in the long run by reducing the need for repairs.

Regular air compressor maintenance is an investment that pays off in the form of improved performance, longevity, and safety. By following these tips and consulting your manufacturer's manual, you can ensure that your air compressor continues to serve you reliably for years to come. And if you ever encounter issues beyond your expertise, don't hesitate to seek assistance from a qualified Detroit air compressor company or technician.

Remember, a well-maintained air compressor isn't just a tool; it's a valuable asset that can enhance your productivity and save you money. With proper care, your air compressor can continue to be a reliable workhorse, empowering you to tackle your projects with confidence and efficiency.

Leave your comments

Post comment as a guest